With a core belief in continuous product innovation and development to meet the changing industry needs, especially with new developments in foam, rubber and plastic materials; we provide effective & efficient cutting-edge solutions for close tolerance cutting and low minimum thickness.

Application Type

Machine List

Carousel Splitting

S 41

Reinforced cutting unit for splitting & stacking of higher density foam into sheets.

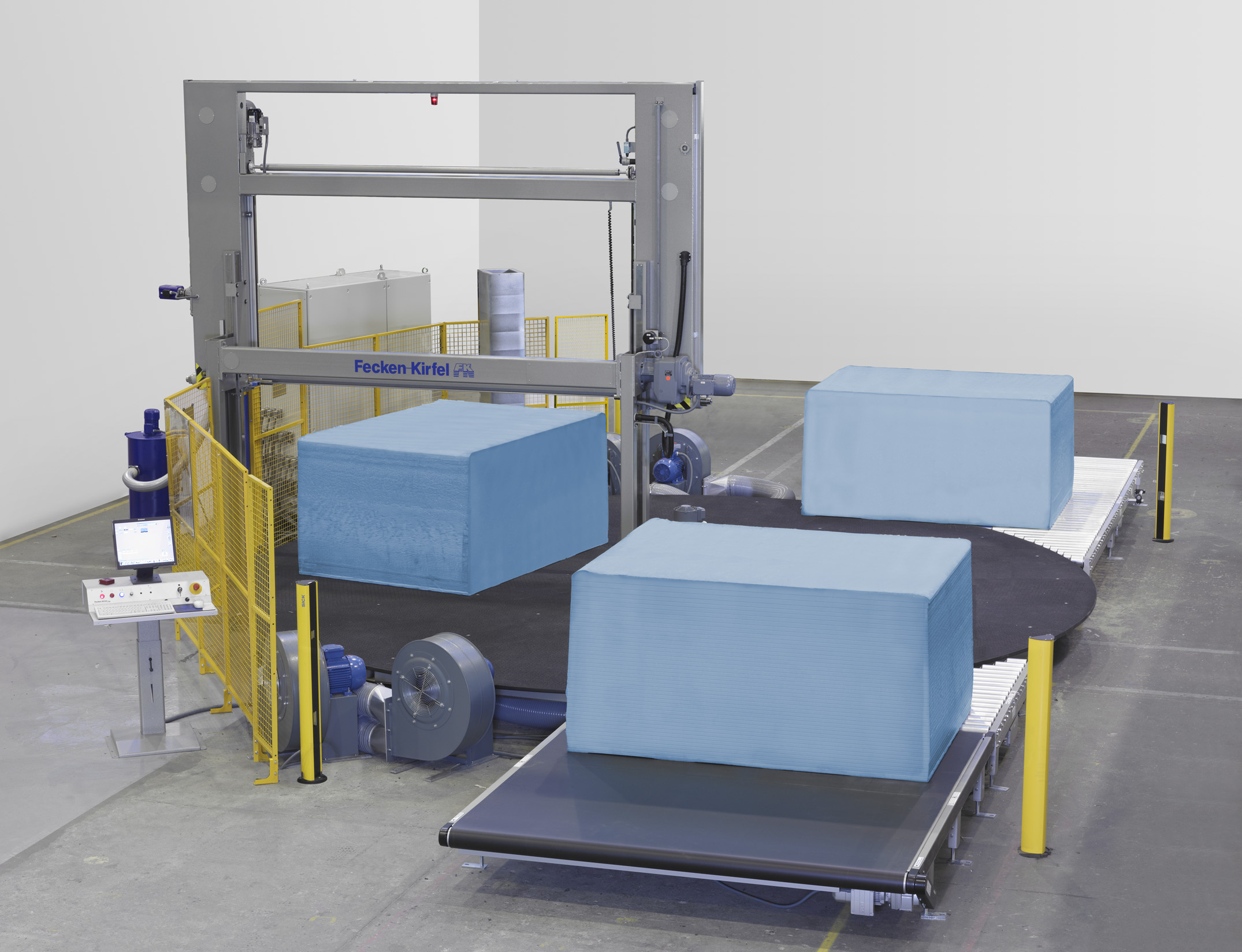

Carousel Splitting

S 24

Automatic splitting & stacking of multiple blocks of PU foam into thin sheets on a circular platform.

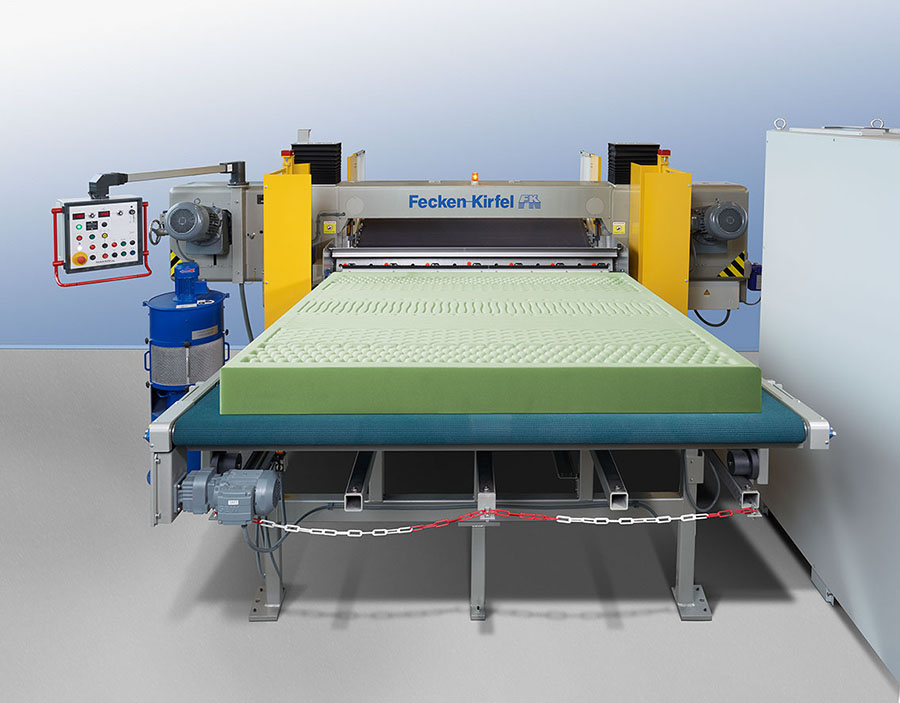

Horizontal Contour Cutting

C 55-56-57

C 56 has 25 m/min high cutting speed and excellent cutting precision for any kind of contour cuts.

Horizontal Contour Cutting

C 66-67

Horizontal Contour Cutting with cutting speed excelling at 70 m/ min.

Horizontal Contour Cutting

C 68-69

Horizontal Contour Cutting is driven by special oscillating knife to get sharp-edge corners.

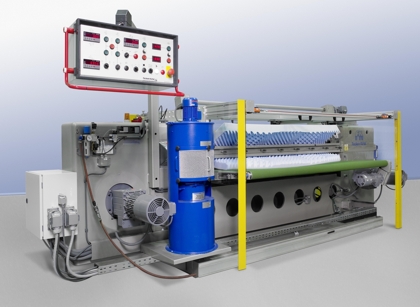

Profile Cutting (Convoluting)

D 21

Profile Cuttng for efficient & economical Profiling of slabs made of flexible PU

Profile Cutting (Convoluting)

D 31

Profile Cuttng to profile highly-condensed and hard materials up to 300 mm thick

Compression Cutting

D 5

Compression Cutting suitable for 3 dimensional symmetrical shaped parts using template

Vertical Contour Cutting

F 62

Vertical Contour Cutting for its fast cutting speed and bandknife can twist ± 360°

Horizontal Splitting

G 1

Type G cut slabs made of rubber and solid plastic materials with hardness 50 -95° Shore A

Horizontal Splitting

G 11

Type G 11 cut similar materials to G1 but equips with wind-off & wind-up for rolls

Horizontal Splitting

H 24 A

Fully automatic splitting of Neoprene, PE foam & etc into thin sheets on sliding table

Horizontal Splitting

H 24 E

Fully automatic splitting of semi-rigid foam (headliner) into thin sheets on sliding table

Horizontal Splitting

H 24 T

Fully automatic splitting of fine-celled special foams into sheets between 0.3 – 1.0 mm

Horizontal Splitting

H 32

Fully automatic splitting of heavy PU foam, rebond foam up to density of 200 kg/m³

Horizontal Splitting

H 32 LF

Loop cutting line integrated with loop conveyor system for production of roll foam

Horizontal Splitting

H 42 A

Fully automatic splitting of Neoprene, PE foam & etc in thin sheet or roll good

Horizontal Splitting

K 21

Horizontal splitting K 21 cut materials up to hardness 30-70 degree Shore A

Horizontal Splitting

R 21-88

Peeling machine R22/88 cut PU foam blocks into long thin foils (or rolls) on confined area

Horizontal Splitting

R 22 E

Peeling machine R22 E cut reboned foam blocks into long thin foils (or rolls) on confined area

Cross Cutting

T 2

Cut-off machine T2 uses bandknife and cuts are made from top to bottom

Cross Cutting

T 4

Cut-off machine T4 uses oscillating knife and cuts are made from left to right & return

Trimming

T 8-T 8 S

Automatic Cut-off and Trimming machine T8 can also dividing cut to different block sizes

Trimming

V 116

Automatic side trimmer V 116 for trimming long block in cutting line

Horizontal Splitting

W 21-22

Automatic horizontal splitting & stacking machine W21 with sliding table for PU foam

Peeling

R 24

Peeling machine R 24 cut cork, PU bonded shredded rubber, PU elastomer into thin foils

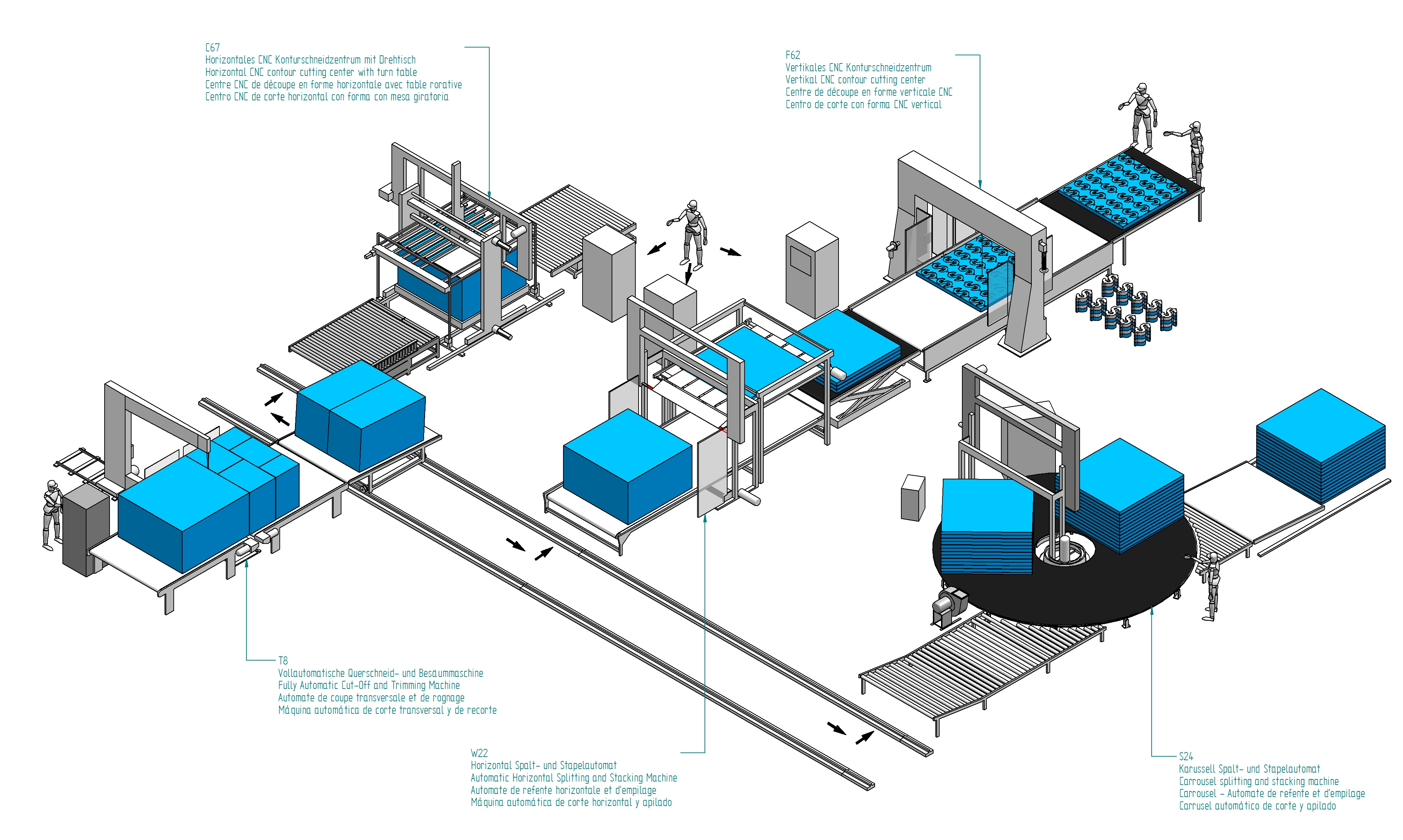

Cutting Line

Cutting Line

Fully automatic and customisable cutting systems to match your production requirements for an incredibly effective & efficient solution.